Research Fields

The fields of research at ZAL reflect both current tech trends and core topics within the aviation industry. The diversity of topic is a strength at ZAL because it’s the combination of technologies and topics that fosters innovation. This is complemented by the exceptional network of in-house experts and state-of-the-art research facilities at the ZAL TechCenter.

Innovation Accelerator

You want to be innovative, but you lack the idea? Or you have an idea and are struggling with implementation? We say: Anyone can innovate! And show you how.

External partners have long benefited from our expertise in innovation management. Together we design the innovation process from idea generation to prototype.

We apply specially tailored methods and work with our customers to develop new business areas and product visions. In addition, we support the selection of suitable partners and help with the implementation of prototypes by integrating ZAL’s internal interdisciplinary technology expertise and infrastructure. With the help of our comprehensive service, you will achieve a fast and sustainable result.

Did you know that 80% of the success of innovations depends on the right project selection? In our way of working we pay increased attention to this. We work according to the “fail fast” principle. Because we know that a fast failure is better than a late one. It simply reduces the risks during the market launch and ensures your success.

Do you have questions or are you interested in exchanging ideas? We look forward to hearing from you!

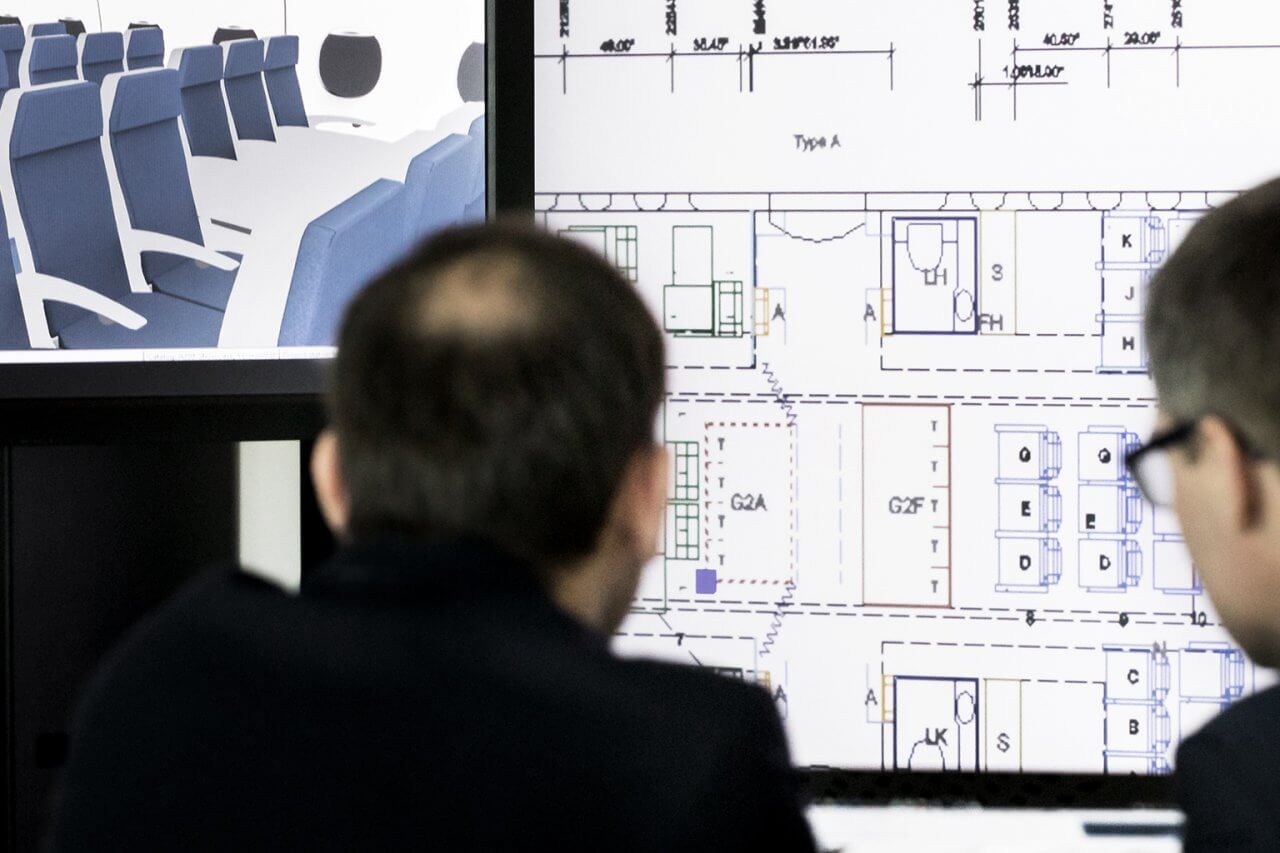

Intelligent Digital Cabin

Into the digital age! The intelligent Digital Cabin challenges the assumptions about flight efficiency. It promises further cost savings for airlines through optimized maintenance, cabin, and ground operations. However, these smart functionalities need to be fully integrated into new digital ecosystems. Our cabin team provides tailor-made Internet of Things (IoT) solutions for aircraft, including definition, development, and integration tests.

Get in touch and let’s design the cabin of the future together!

If you’d like more information, please have a look at our Intelligent Digital Cabin flyer here.

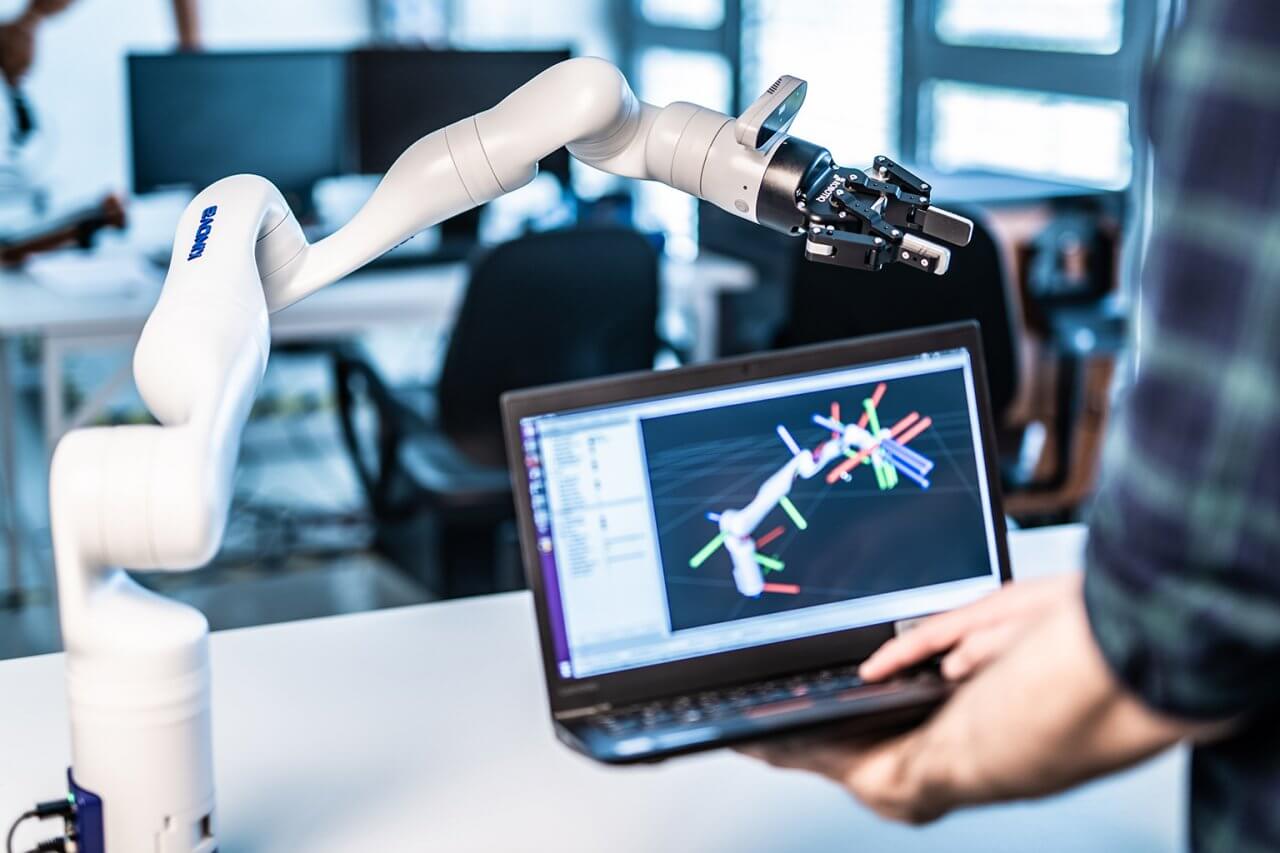

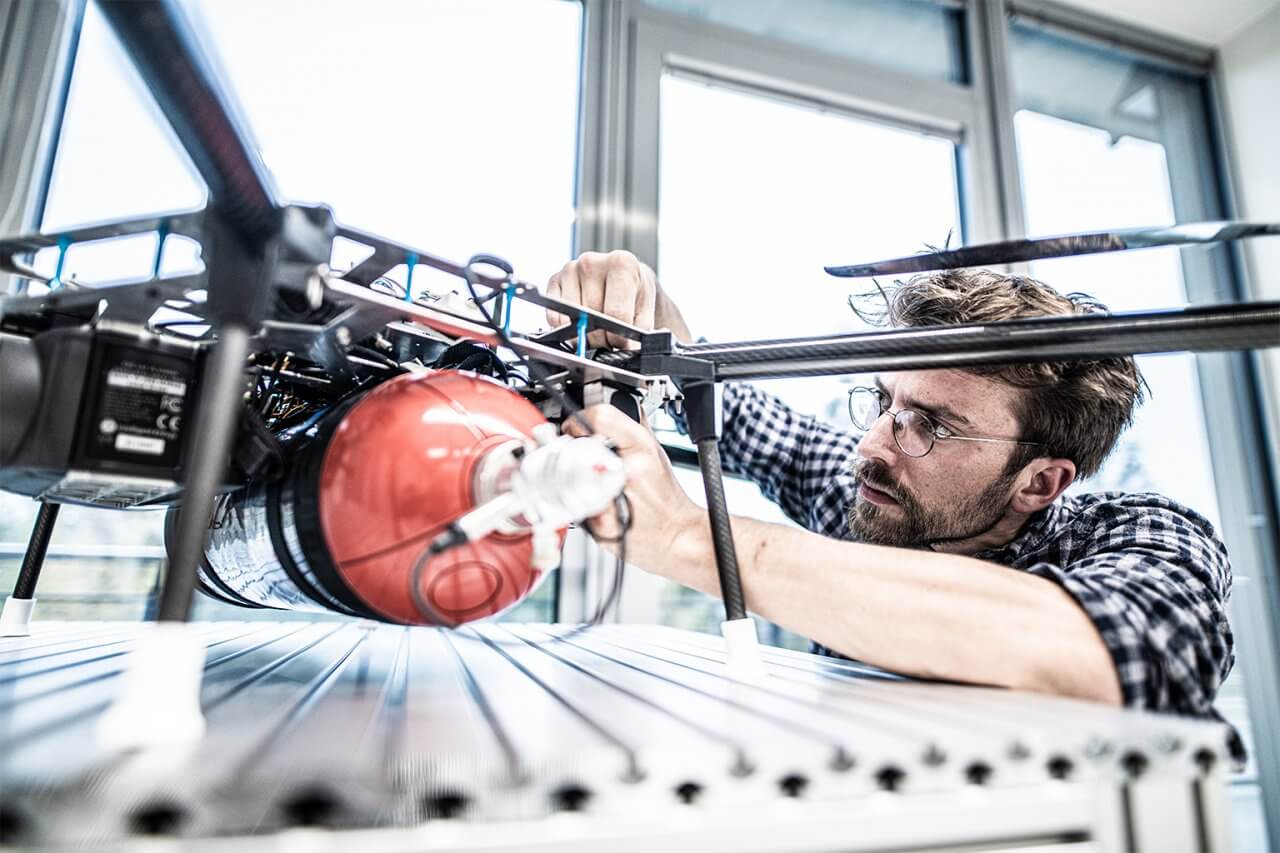

Robotics & Automation Technology

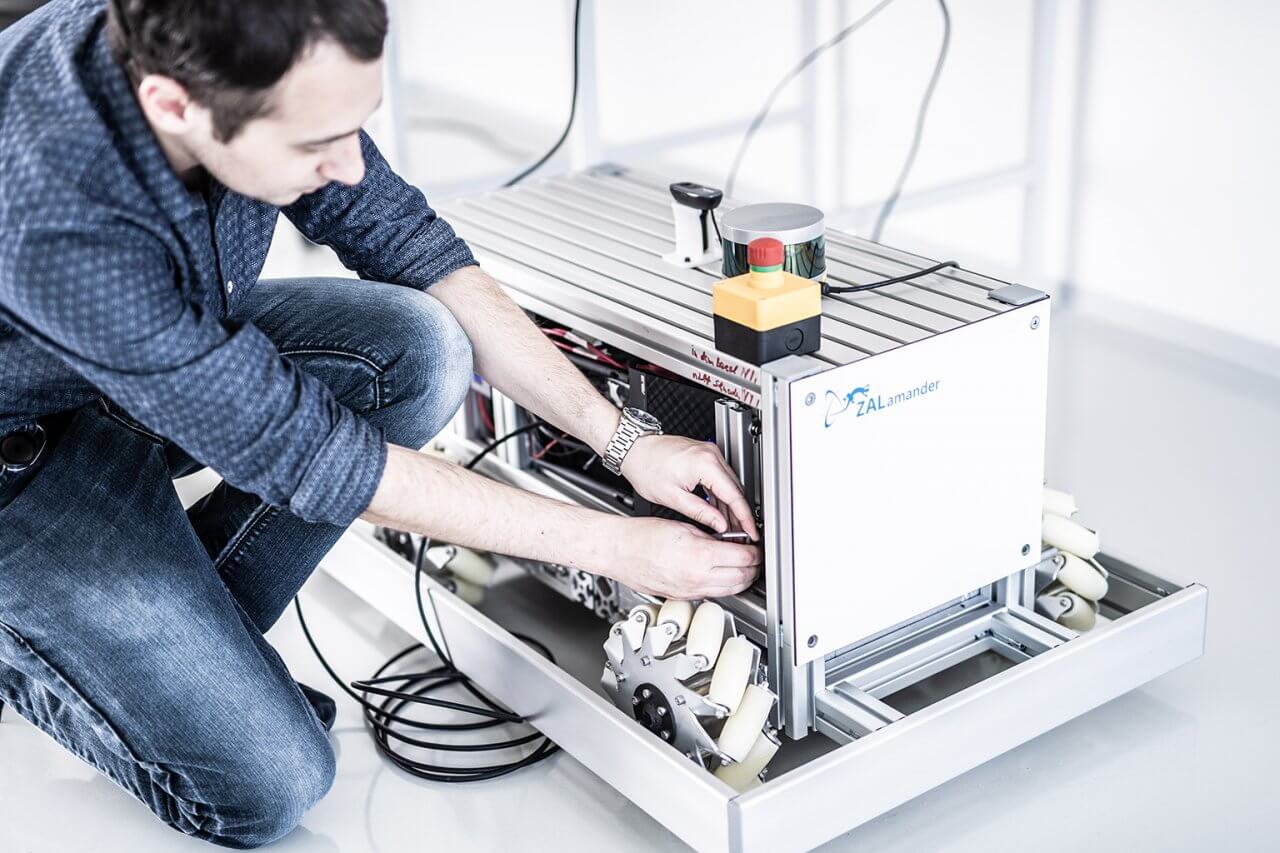

Human or robot, who will set the agenda? The recent developments in the field of human-machine interaction enable us now to work hand in hand with robots in the tightest of spaces. This progress is an important step forward in the aviation industry towards increasing automation.

How good is your relationship with your robot colleague? Do you need support in the areas of conventional automation and industrial robotics or advice on mobile robots or collaborative robot arms? As a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off!

If you’d like more information, please have a look at our Robotics & Automation flyer here.

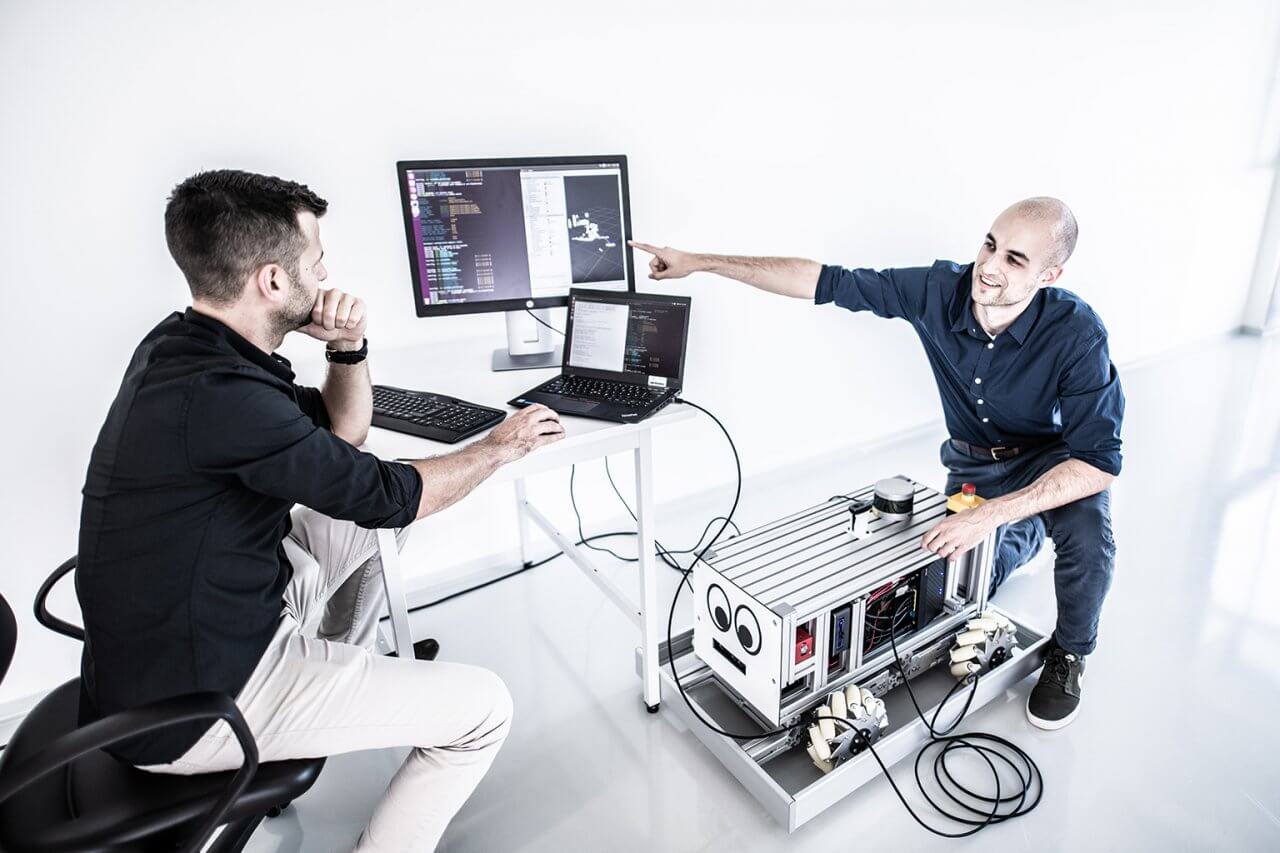

Industrial Artificial Intelligence (AI)

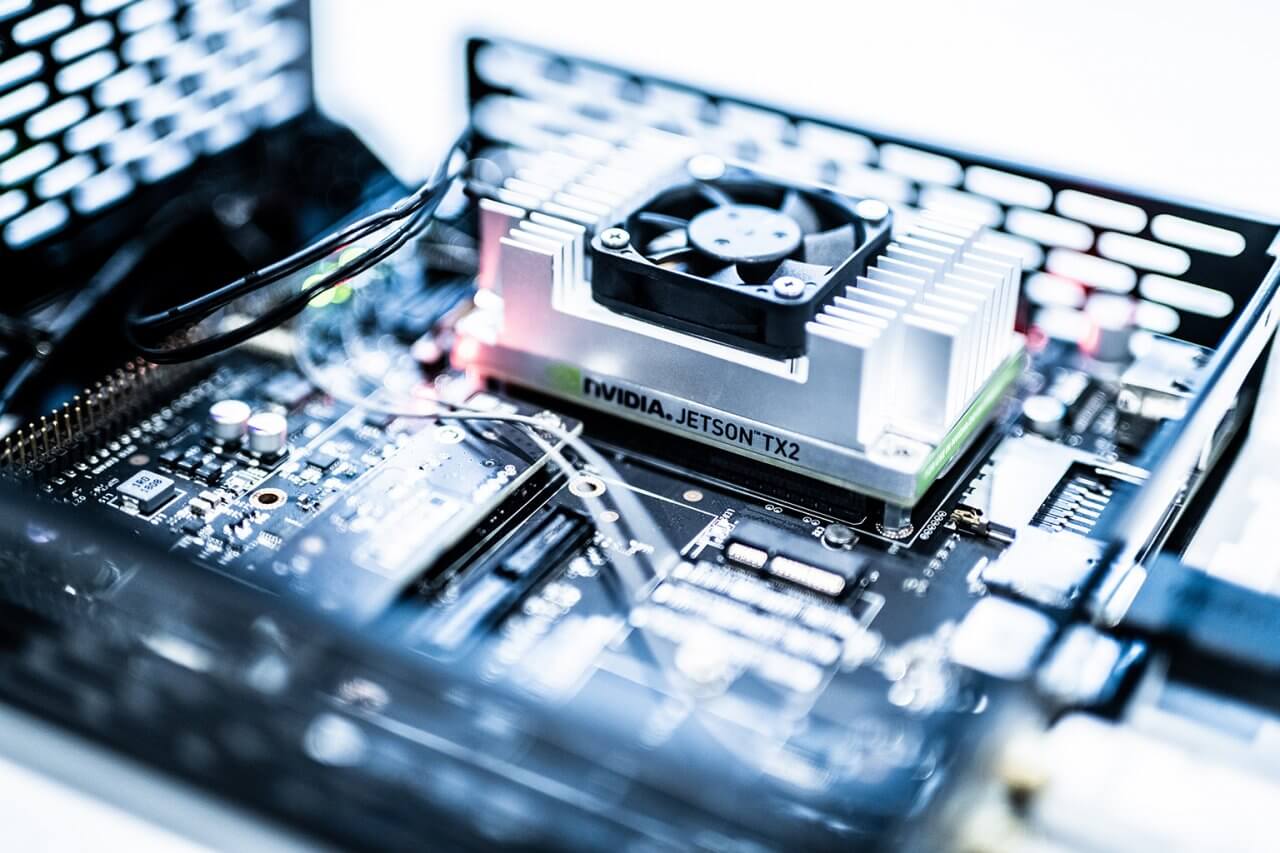

Where can AI support you? Artificial intelligence (AI) has become indispensable in many areas of daily life. In particular, complex tasks such as image processing or voice recognition are solved more effectively with modern AI methods than with classical programming methods. In the field of industrial AI, we deal with the question of how AI algorithms can be used in the aviation industry. AI can inform logical thinking, reasoning, planning, exploring, navigating and manipulating objects. This supports process monitoring, quality assurance and predictive maintenance.

We guide the entire chain process of implementing AI algorithms. This starts with data acquisition from test benches or simulations. It extends to the training of suitable learning algorithms and ends with the optimization of the selected model. We are also happy to advise and support potential users in the implementation of an AI project. Our AI Aviation Lab owns an infrastructure with computing capacity, a multitude of sensors and a collaborating robot for this end.

As the Research & Technology team of a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off! Get in touch!

If you’d like more information, please have a look at our Industrial AI flyer here.

Data Acquisition & Processing

Big Data – the generation, consolidation and evaluation of large amounts of data has great potential for aviation. Correctly run data analyses can be translated into recommendations for action and lead to optimization, e.g. in MRO processes.

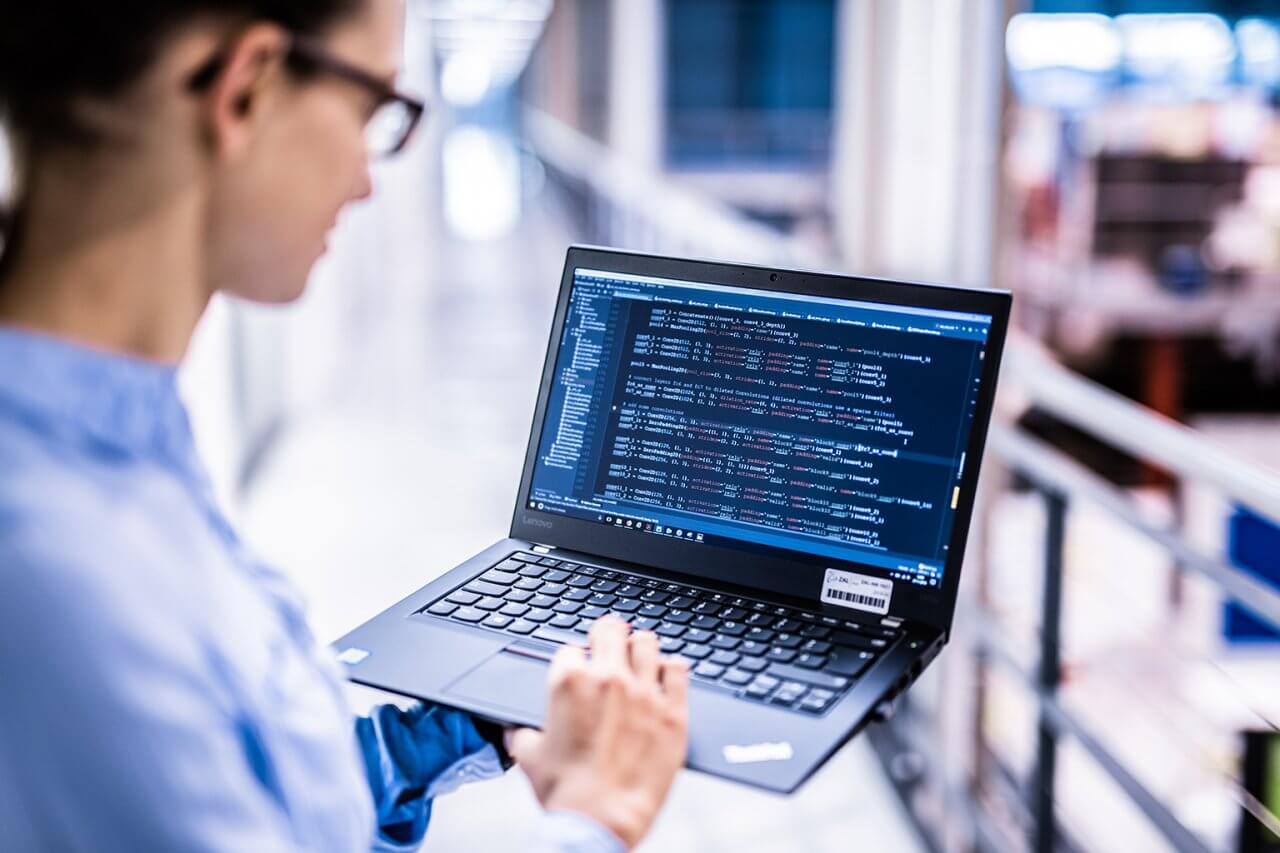

These analyses often consider data from different sources and require high conceptual, programming and numerical skills. The ZAL Research & Technology team of experts develops solutions for the efficient acquisition of sensor data and the generation of virtual data. These virtual data represent reality and can therefore be used for training learning systems.

Complex problems often cannot be solved with classical, rule-based programming or only with extremely high effort. ZAL therefore uses machine learning and deep learning algorithms to develop models which enable the optimization and digitalization of processes of the aviation industry.

As the Research & Technology team of a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off! Get in touch!

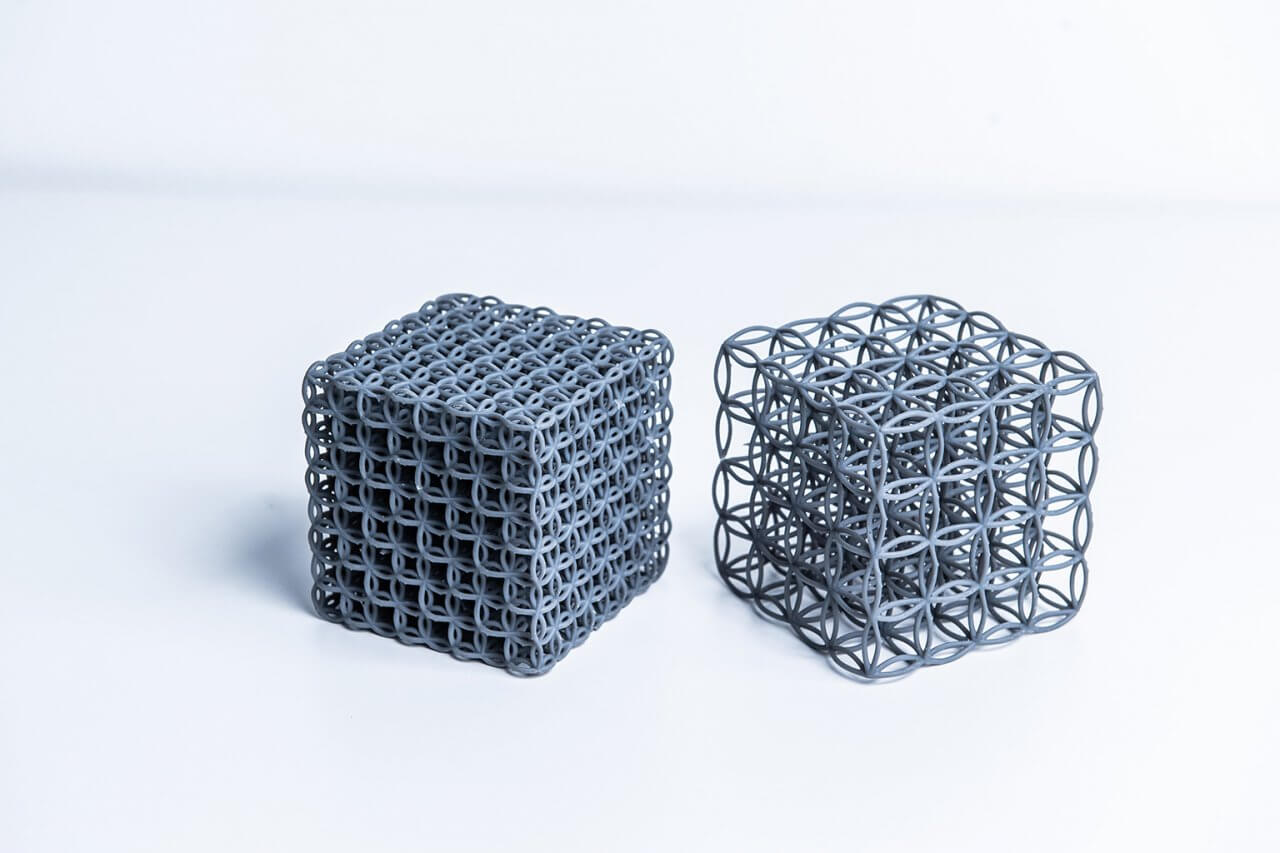

Additive Manufacturing

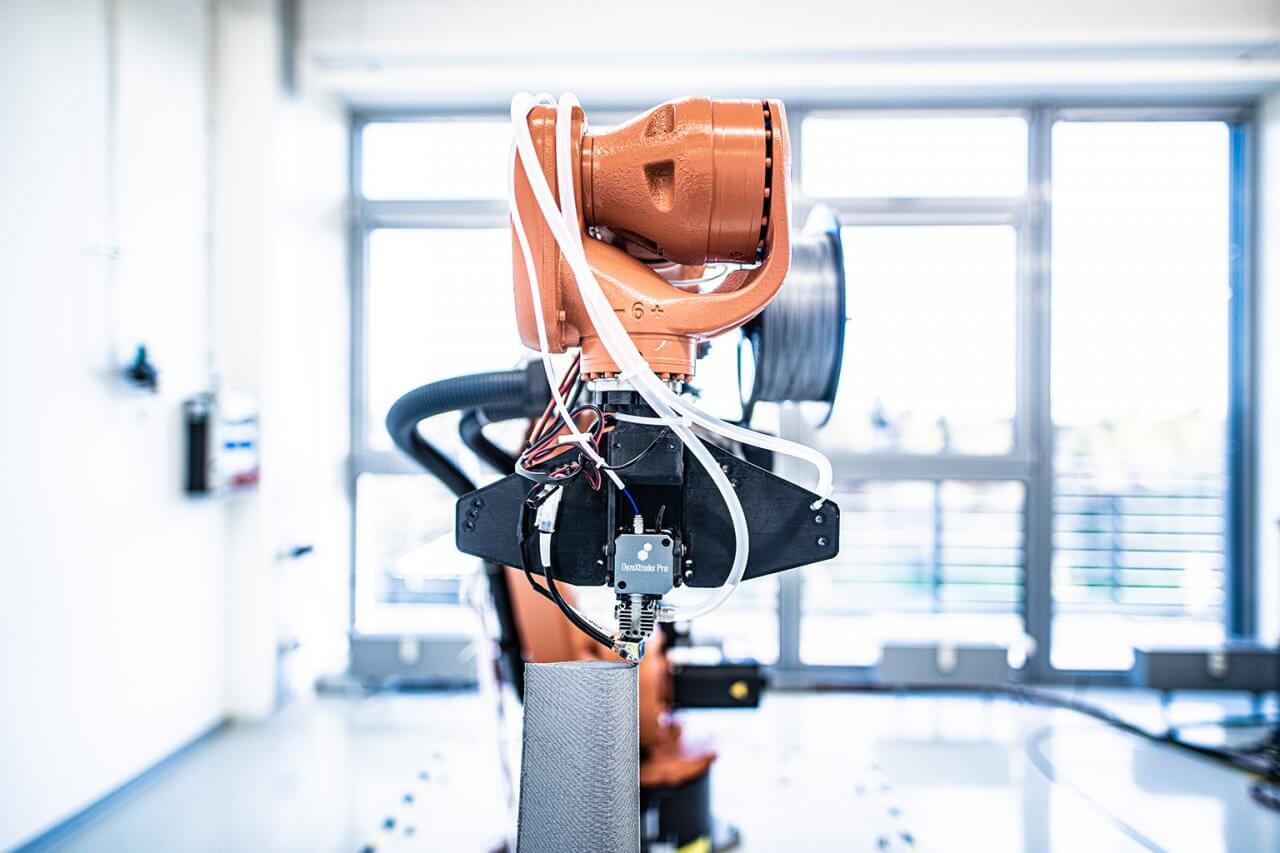

3D printing is revolutionizing aircraft manufacturing. More than 300 printed components are already in use in the new Airbus A350. Additive manufacturing (AM) makes it possible to combine several functions in one component. This opens up completely new ways of redesigning existing components while at the same time reducing weight.

Our AM team specializes in hybrid manufacturing, robot-led additive manufacturing and function integration. We would be pleased to support you with your AM project. We develop processes and prototypes tailored to your needs. With new AM technologies can also integrate the most diverse functions into your product through.

As the Research & Technology team of a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off! Get in touch!

If you’d like more information, please have a look at our Additive Manufacturing flyer here.

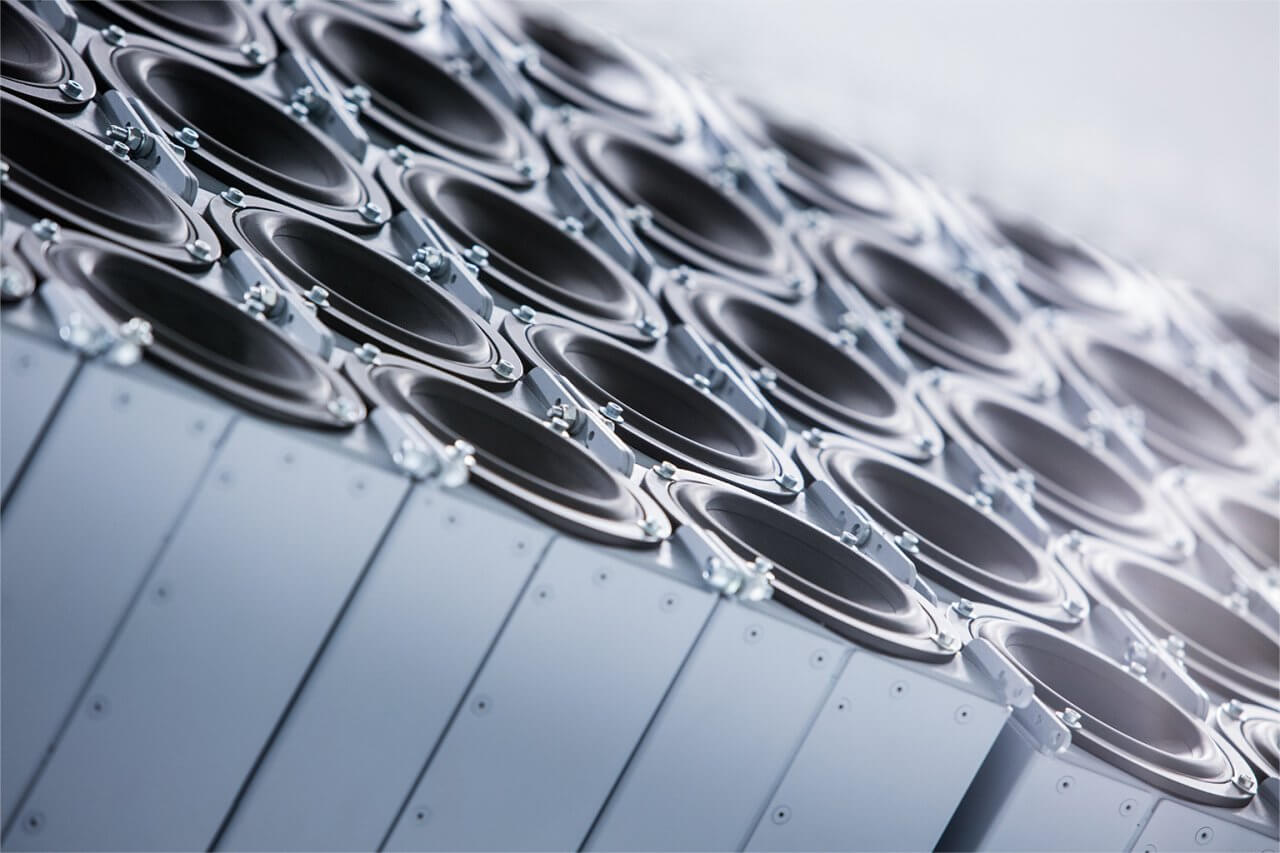

Acoustics & Vibration

How can we make flying more pleasant for passengers? We know that a positive flying experience is closely linked to an optimized cabin environment with reduced noise and vibration. These vibration problems we address by developing acoustic cabin concepts. For this purpose, we are working in the ZAL Acoustics Lab on the unique Acoustic Flight Lab Demonstrator. Our work focuses on sound and vibration measurement, vibro-acoustic simulation, testing new materials and developing new electro-acoustic audio systems.

As the Research & Technology team of a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off! Get in touch!

If you’d like more information, please have a look at our Acoustics Vibration flyer here.

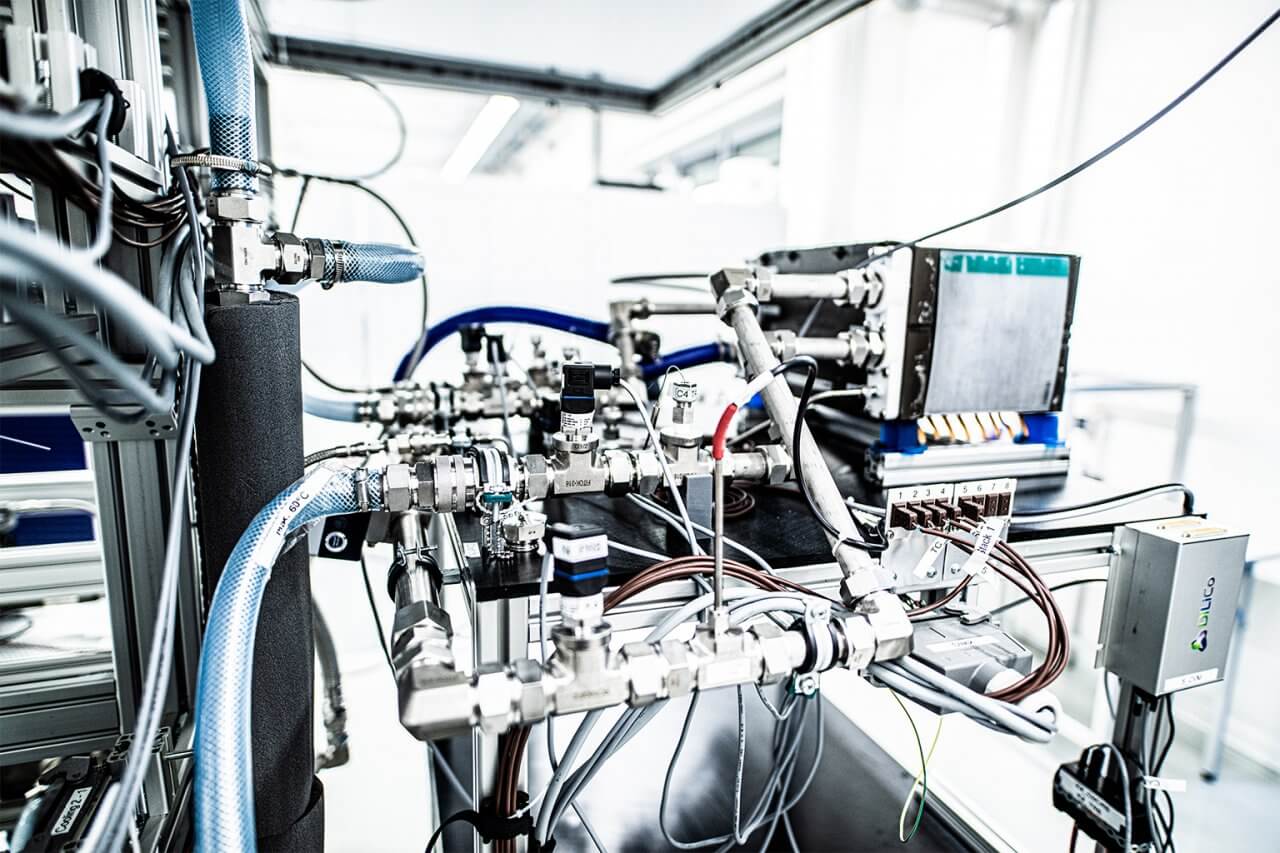

Fuel Cell & Electrical Power Systems

Towards emission-free flight: Our daily work is aimed at advancing the technological maturity of fuel-cell systems. Electrical systems powered by fuel cells are an environmentally friendly and efficient possibility ensuring the electrical power supply of today’s and tomorrow’s aircraft and thereby reducing emissions. The potential for clean mobility and efficient power and heat generation is also relevant for other industries. For this reason, the ZAL Fuel Cell Lab also cooperates with cross-sector partners, e.g. from the automotive and shipping industry.

Let us calculate the most important qualities of a fuel cell system for you here without obligation! As the Research & Technology team of a small Mittelstand company, we are also the ideal partner when it comes to fast and agile technology solutions. From consulting and feasibility studies to project solutions and customized prototypes – we are happy to help your vision take off!

For more information, please check out our Fuel Cell Electrical Power Systems flyer here.